CDF4848B-086

Appearance

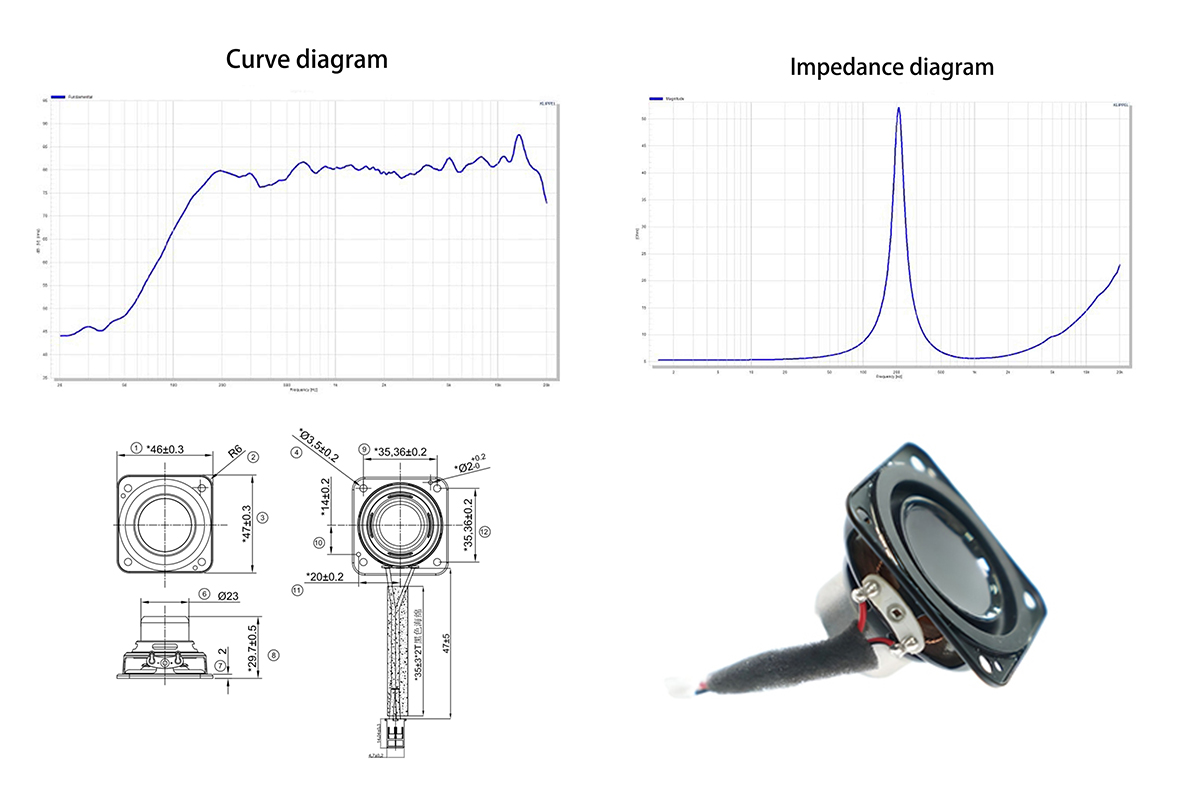

Structure (Figure 1): Square black plastic shell with mounting holes at four corners. The center is a metal diaphragm with QR Code printed on it for production traceability. A red (positive pole) and a black (negative pole) lead are connected, a white connector is arranged at the end of the lead, and a black shockproof net is sleeved.

Connection mode (Figure 2): Another view shows that the unit is connected to a metal pin connector through a flexible circuit board (FPC). This type of connection is ideal for internal connections where space is limited and high reliability is required.

Features

Highly integrated connection: FPC connectors or prefabricated cables are used to facilitate fast and accurate docking with the host motherboard and reduce assembly errors. Clear polarity identification: the red and black lines clearly distinguish the positive and negative poles to prevent wiring errors. Robust installation: Square housing and multiple mounting holes ensure firm fixation inside the equipment and vibration resistance. Professional quality: The Olympus brand usually means excellent manufacturing and reliable quality, suitable for professional environments.

Advantages

Plug and play: Prefabricated connectors or FPC connectors greatly simplify the production assembly process and improve efficiency. High reliability: FPC connection is more resistant to vibration than welding, and the contact is stable; the shockproof net of the cable protects the wire. Easy maintenance: The modular design means that the entire unit can be quickly replaced after damage.

Instructions

Installation and fixation: Align the speaker unit with the installation position inside the equipment, and fix it with screws through the four corner holes. Electrical connection: accurately connect the white connector (or FPC connector) to the corresponding socket on the main board of the device. Pay attention to the direction to ensure that the insertion is not reversed or misaligned. Test: Perform the function test after the connection is completed.

Application Scenarios

Household appliances: Microwave ovens and washing machines with sound units that indicate when an operation is complete.

Security equipment: Doorbells, smoke alarms, and door sensors with sound generators.

Office equipment: Status alarms for fax machines and time clocks.

Electronic toys: Toys that produce various sound effects.

Industrial control: Instruments, control panel buttons, or alarms.

FAQ

Q1: What is your MOQ?

A: Our standard MOQ is 100 units for regular models. We can offer a lower MOQ for pilot orders, but the unit cost will be higher.

Q2: Can we customize the color or material of the speaker?

A: Yes. Color and material customization is available for OEM/ODM orders. Please contact us with your specific requirements for a quotation.

Q3: Do you provide ODM/OEM services?

A: Yes, we specialize in ODM and OEM services. We can design and produce speakers according to your technical specifications or design drawings.

Q4: How long does it take to develop a new product?

A: The development time depends on the complexity. It typically takes 4-8 weeks for a new design, including prototyping and testing.

Q5: What are your payment terms?

A: We commonly accept T/T (Bank Transfer). For new customers, 50% deposit is required to start production, and the balance 50% before shipment.

Q6: Can I mix different products in one container?

A: Yes, mixed orders are welcome. This is a cost-effective way to import. We will provide a detailed packing list for each product.

Company Overview

Jiangxi Roxound Acoustic Company was established in 2006 and is a professional speaker manufacturer with 20 years of acoustics experience. It has established manufacturing bases in Dongguan, Jiangxi, and Vietnam. The company's products are mainly used in consumer electronics, security systems, automobiles, musical instruments, micro-sized devices, and professional applications.

We are dedicated to providing high-quality speaker units and comprehensive solutions, including free EQ and DSP tuning, passive radiator, and duct design support. Leveraging simulation software such as Finemotor, a reliability design standard library, and a pre-design database accumulated over 15 years, we ensure efficient and reliable development. We can deliver samples within 3 days, complete projects within 7 days, and have access to a professional soundproof room to guarantee the precision of acoustic testing and verification.