CDF4848A-103

Appearance

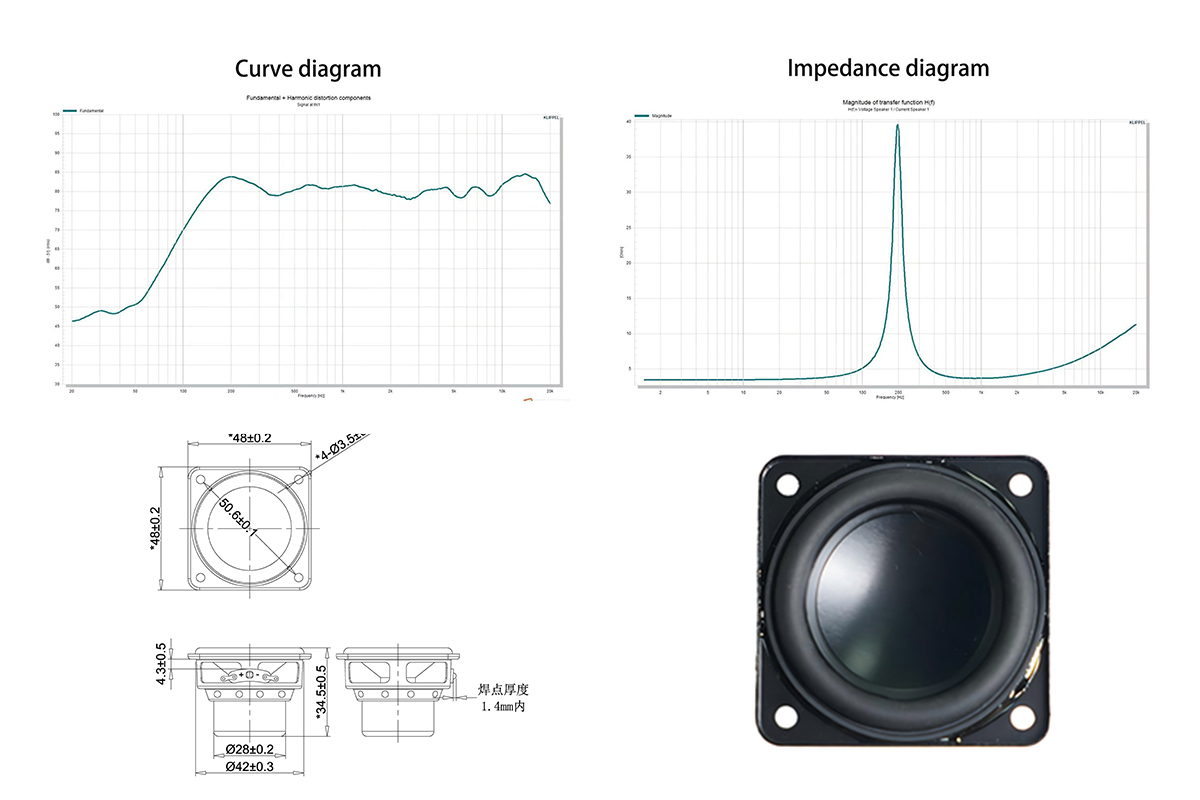

Front (Picture 1): Square black plastic basin frame with round mounting holes at the four corners. The center is a round black diaphragm, and the edges are surrounded by a wide black rubber suspension, providing compliant support and long-stroke potential.

Side/diaphragm close-up (Figure 2): Shows the side thickness of the unit, the details of the rubber suspension, and the silver-gray metal diaphragm (or cone). There are screw holes for fixing on the edge of the basin frame.

Features

Core Voicing: Convert electrical signals into sound.

Robust installation: The square basin frame and multiple mounting holes ensure stability and firmness after installation and reduce vibration.

Durable design: The rubber overhang has better aging resistance than the foam edge and has a longer lifespan.

Space Optimization: The square casing facilitates efficient use of space for layout inside the device.

Advantages

Firm installation: multi-point installation, good resistance to mechanical vibration.

Stable performance: The rubber overhang has little performance change under different temperature and humidity environments.

Easy integration: Standard appearance and installation methods facilitate product design integration.

Instructions

Installation and fixation: Align the speaker unit with the opening of the equipment panel, and use screws to lock it through the mounting holes on the basin frame. Pay attention to applying even force diagonally to avoid deformation of the basin frame.

Circuit connection: Solder the audio cable to the speaker's terminal block (not directly shown in the picture, usually located on the side or back of the basin frame). Be sure to pay attention to the polarity (positive and negative), reverse connection will affect the sound quality.

Drive matching: Use a power amplifier circuit with impedance and power matching for driving to avoid overloading.

Application Scenarios

Household appliances: sound units for washing machines and microwave ovens.

Automotive electronics: car speakers, alarm sounds.

Public broadcasting: background music system, paging speakers.

Consumer electronics: portable radios, multimedia speakers.

Security equipment: doorbells, alarms.

FAQ

Q1: What is your MOQ?

A: Our standard MOQ is 100 units for regular models. We can offer a lower MOQ for pilot orders, but the unit cost will be higher.

Q2: Can we customize the color or material of the speaker?

A: Yes. Color and material customization is available for OEM/ODM orders. Please contact us with your specific requirements for a quotation.

Q3: Do you provide ODM/OEM services?

A: Yes, we specialize in ODM and OEM services. We can design and produce speakers according to your technical specifications or design drawings.

Q4: How long does it take to develop a new product?

A: The development time depends on the complexity. It typically takes 4-8 weeks for a new design, including prototyping and testing.

Q5: What are your payment terms?

A: We commonly accept T/T (Bank Transfer). For new customers, 50% deposit is required to start production, and the balance 50% before shipment.

Q6: Can I mix different products in one container?

A: Yes, mixed orders are welcome. This is a cost-effective way to import. We will provide a detailed packing list for each product.

Company Overview

Jiangxi Roxound Acoustic Company was established in 2006 and is a professional speaker manufacturer with 20 years of acoustics experience. It has established manufacturing bases in Dongguan, Jiangxi, and Vietnam. The company's products are mainly used in consumer electronics, security systems, automobiles, musical instruments, micro-sized devices, and professional applications.

We are dedicated to providing high-quality speaker units and comprehensive solutions, including free EQ and DSP tuning, passive radiator, and duct design support. Leveraging simulation software such as Finemotor, a reliability design standard library, and a pre-design database accumulated over 15 years, we ensure efficient and reliable development. We can deliver samples within 3 days, complete projects within 7 days, and have access to a professional soundproof room to guarantee the precision of acoustic testing and verification.