CDF4848A-076

Appearance

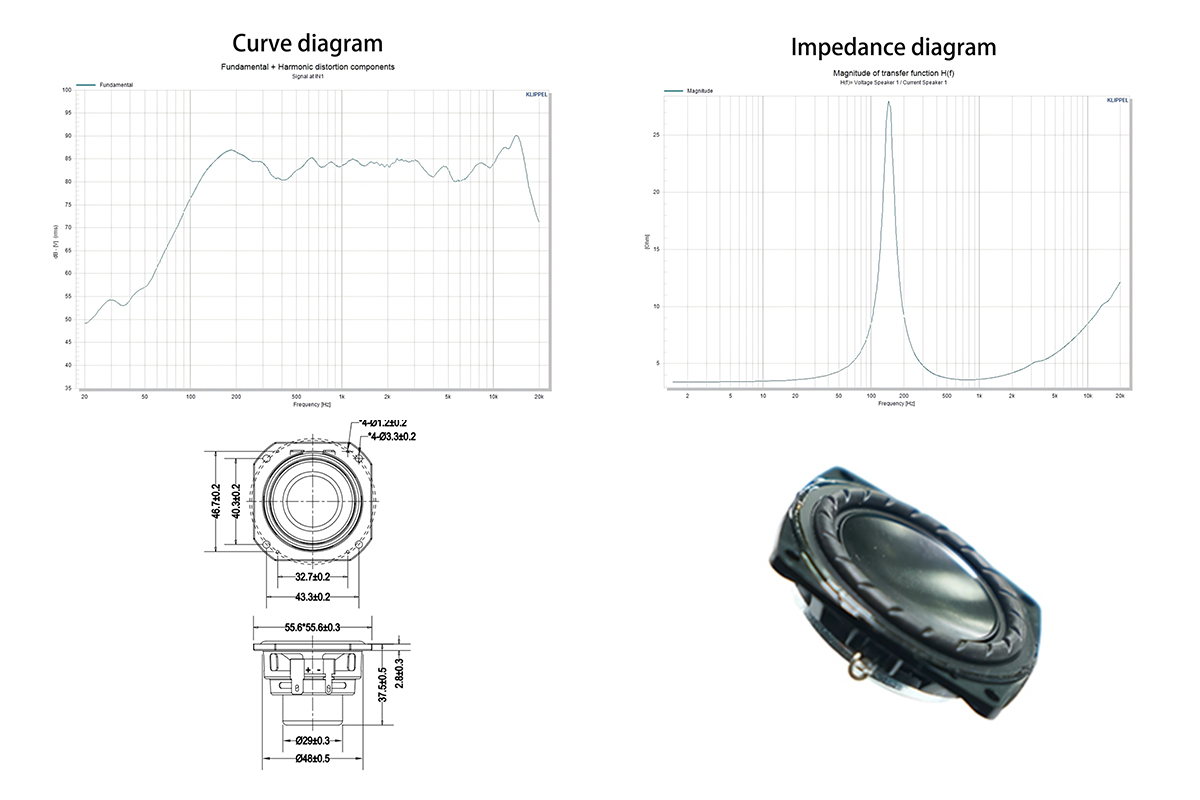

Front (Figure 1, Figure 3): Square black plastic shell with round mounting holes at four corners. The core is a circular sound structure, the most distinctive feature of which is a black rubber edge with a unique concave and convex pattern (similar to tire pattern), which contributes to sound diffusion and physical protection. The center is a silver-gray diaphragm.

Back (Figure 2): shows a square backplate with four small holes in the central area (possibly for acoustic tuning or heat dissipation) and a product information label.

Material and process: The shell is made of plastic, the diaphragm is made of metal or composite material, and the rubber edge provides good compliance.

Features

Special rubber edge design: the "tread" rubber edge not only protects the diaphragm, but also may optimize the sound diffusion characteristics to a certain extent and reduce the front cavity effect. Standard impedance: 4 Ω impedance is easily driven by common audio power amplifier chips. Compact square design: Square housing saves installation space and facilitates compact layout inside the device. Robust installation: four corner mounting holes ensure firm fixation and reduce vibration during operation.

Advantages

Physical protection: the protruding rubber edge can effectively prevent direct impact on the diaphragm during installation or transportation. Efficient space: The square shape can make more effective use of the internal space of the equipment than round horn of the same size. Easy installation: standard hole design, easy integration.

Instructions

Installation and fixation: Align the speaker unit with the opening of the equipment panel, and use screws to lock it through the mounting holes at the four corners. Pay attention to the uniform force to avoid crushing the rubber edge. Circuit connection: correctly solder the audio output cable to the pin on the back of the speaker (the pin should be hidden in the small hole in the middle of Figure 2). Be sure to pay attention to the polarity, and distinguish the positive and negative poles according to the specifications or marks. Drive matching: Use a power amplifier circuit matched to a 4 Ω load to avoid exceeding the rated input power.

Application Scenarios

Portable devices: Bluetooth speakers, portable radios.

Vehicle electronic: the prompt sound unit of vehicle navigation and driving recorder. Security equipment: doorbell, alarm sounder. Household appliances: smart home sensors, small home appliances prompt sound unit. Communication equipment: receiver of interphone and telephone.

FAQ

Q1: What is your MOQ?

A: Our standard MOQ is 100 units for regular models. We can offer a lower MOQ for pilot orders, but the unit cost will be higher.

Q2: Can we customize the color or material of the speaker?

A: Yes. Color and material customization is available for OEM/ODM orders. Please contact us with your specific requirements for a quotation.

Q3: Do you provide ODM/OEM services?

A: Yes, we specialize in ODM and OEM services. We can design and produce speakers according to your technical specifications or design drawings.

Q4: How long does it take to develop a new product?

A: The development time depends on the complexity. It typically takes 4-8 weeks for a new design, including prototyping and testing.

Q5: What are your payment terms?

A: We commonly accept T/T (Bank Transfer). For new customers, 50% deposit is required to start production, and the balance 50% before shipment.

Q6: Can I mix different products in one container?

A: Yes, mixed orders are welcome. This is a cost-effective way to import. We will provide a detailed packing list for each product.

Company Overview

Jiangxi Roxound Acoustic Company was established in 2006 and is a professional speaker manufacturer with 20 years of acoustics experience. It has established manufacturing bases in Dongguan, Jiangxi, and Vietnam. The company's products are mainly used in consumer electronics, security systems, automobiles, musical instruments, micro-sized devices, and professional applications.

We are dedicated to providing high-quality speaker units and comprehensive solutions, including free EQ and DSP tuning, passive radiator, and duct design support. Leveraging simulation software such as Finemotor, a reliability design standard library, and a pre-design database accumulated over 15 years, we ensure efficient and reliable development. We can deliver samples within 3 days, complete projects within 7 days, and have access to a professional soundproof room to guarantee the precision of acoustic testing and verification.